This TT SILENT-M 200mm extractor from Winflex allows you to renew the air in your grow room.

The extractor renews CO² and ejects depleted air from the grow room while regulating T°.

The extractor's advantage is that the fan is housed in a sound-insulated casing. This extractor is therefore designed to be silent.

Nevertheless, the air is powerful and high-pressure.

Features TT SILENT-M Ø 200mm UN R1 extractor with IEC :

- Ø air outlet: 200 mm

- Equipped with temperature module and electronic speed control to automatically control air flow and motor speed according to the air temperature in your room.

- Speed control knob to adjust motor speed

- Thermostat control knob for temperature set-point adjustment

- Indicator light

- The UN option allows external temperature sensing, with a 4 m long probe attached to the extractor.

- Flow rate: 810 m³/h or 1020 m³/h

- Power consumption: 78 W to 110 W

- Length: 550 mm

- Width: 386 mm

- Height: 295 mm

- The fan with electronic speed and T° sensor control module.

The ideal solution for ventilation of premises with high requirements for permanent temperature control, e.g. greenhouses. The fan with the electronic temperature and speed control module enables automatic control (air quality) of motor speed according to air temperature in the air duct or chamber.

Design:

The outer casing is made of polymer-coated steel. The housing is internally soundproofed with 50 mm of mineral wool. The casing is specially perforated for soundproofing.

The fan housing is fitted with an airtight terminal box for connection to the electrical network.

Motor:

The motor is equipped with thermal switches to prevent overheating and protect the motor.

Service life up to 40,000 hours in non-stop operation.

Mounting:

The fan can be mounted anywhere and at any angle in the duct system. Several fans can be

installed in parallel to achieve maximum airflow.

The fan housing is fitted with hooks for floor, wall or ceiling mounting.

Please note: Cables and mains plug available as optional extras

To further optimize the sound aspect of your installation, consider 200mm wadding soundproofing ducts.

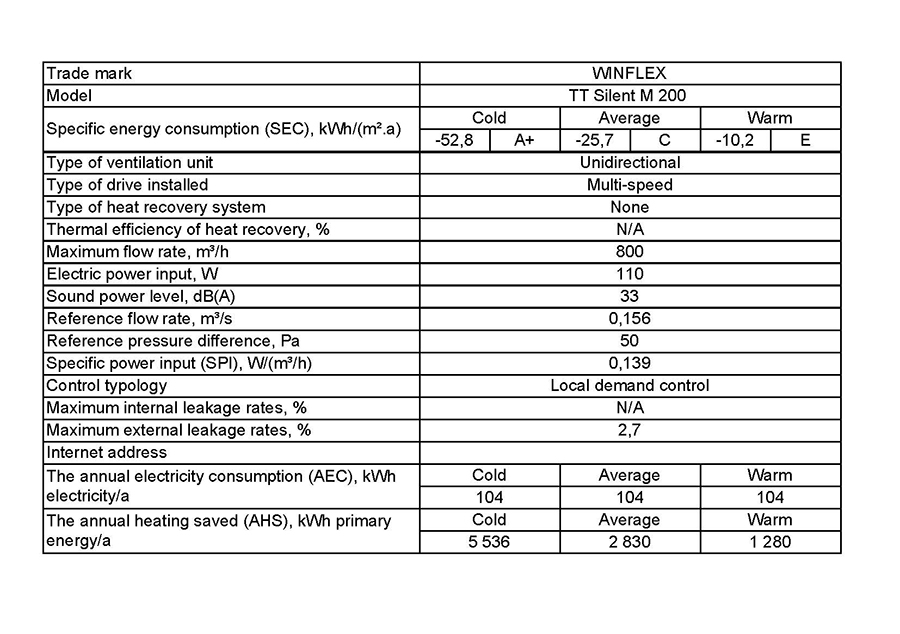

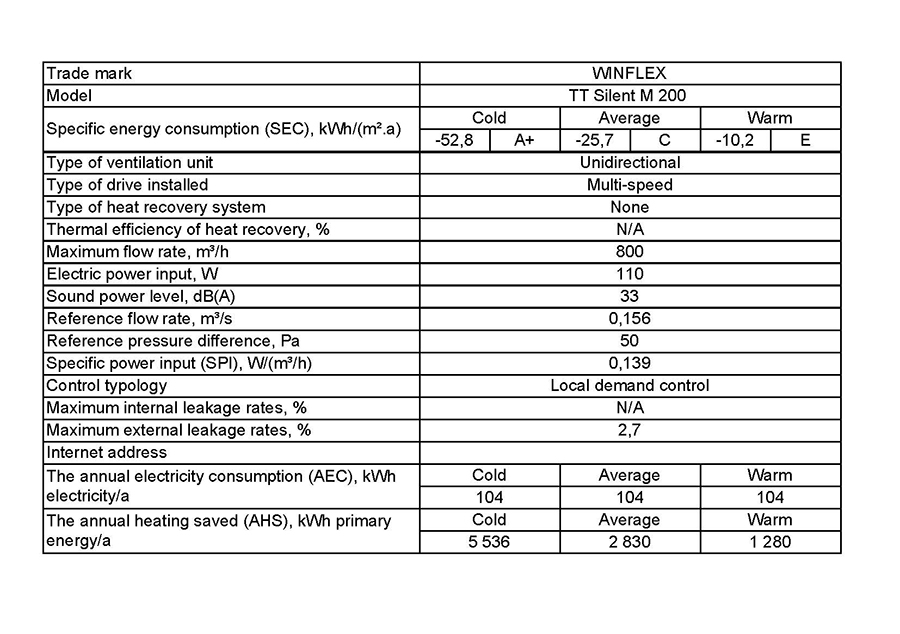

ERP features :

The technical parameters on the ERP energy label and the declaration of performance (DoP) are listed for fan operation at an external pressure of 100 Pa in accordance with EN13141-7:2010.